Bearings are essential components of machines that ensure optimal functioning by restricting the movement of other machine parts to only desired motions. Along with this, they also help in minimizing friction between moving parts. A type of bearing that is commonly used is the needle roller bearing.

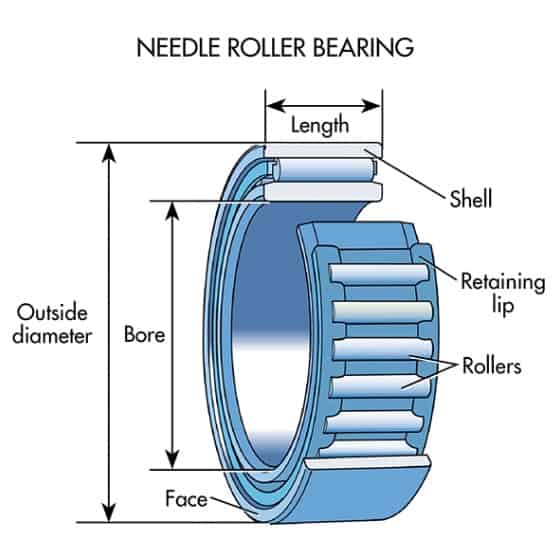

Needle roller bearings are designed for high radial load capacity and consist of cylindrical rollers that are thin and long. They are primarily used in applications where space is limited or where the load capacity requirement is high. The rollers in a needle roller bearing are precisely guided and spaced by a cage.

One of the unique features of the needle roller bearing is its ability to handle high radial loads with relatively less installation space. It is especially useful when the load is transmitted in a radial direction, and axial space is limited. The small diameter of the rollers allows the bearing to handle high loads without taking up much space.

Another benefit of needle roller bearings is that they are highly resistant to shock loads due to their ability to distribute loads evenly over a large contact area. This feature makes them ideal for applications where shocks, vibration, and impact forces are common. Needle roller bearings are also suitable for high-speed applications, thanks to their low operational friction and low heat generation.

There are various types of needle roller bearings available, each with unique features that make them suitable for various applications. One type is the self-aligning needle roller bearing. This bearing is designed with a spherical outer raceway that allows the bearing to self-align itself with the shaft, compensating for any misalignment that may occur.

Self-aligning needle roller bearings are utilized in applications where misalignment may occur due to shaft deflection, installation errors, or thermal expansion. They are widely used in industry sectors such as automotive, construction, and machine tools.

In conclusion, needle roller bearings are essential components of machines that ensure optimal functioning by restricting the movement of other machine parts to only desired motions. They are invaluable in applications where space is limited, and the load capacity requirement is high. Self-aligning needle roller bearings are a popular type of needle roller bearing that compensates for any misalignment that may occur between the bearing and the shaft. These bearings are highly resistant to shock loads, making them ideal for applications where shocks, vibration, and impact forces are common.

Keywords: Needle roller bearings, radial loads, shock loads, self-aligning needle roller bearings.